Actuator information

| Type: | Air bypass control valve |

|---|---|

| Power supply: | 12 V from system relay |

| Signal type: | Varying in duty cycle |

| Signal level: | 0 V to 12 V |

Workings of an idle air control valve

To control the idle speed of an engine, an idle air control valve mechanism can be used. It controls the amount of air that bypasses the throttle valve. This mechanism is commonly used on vehicles with fuel-injection which have no throttle valve controller motor, like e.g. a throttle valve control DC motor or throttle valve position stepper motor.

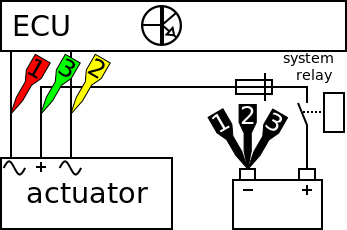

Two different idle air control valves are found, with a single solenoid or with double solenoids, respectively having a 2-pin connection or a 3-pin connection. Both air control valves are mechanically similar in construction. The double solenoid valve uses one solenoid for opening and one solenoid for closing the valve. The single solenoid valve has a spring to pull back the valve in an initial position, usually closed, and the solenoid opens the valve against the spring pressure. Both idle air control valves have a power supply connected to one side of the solenoid(s) and the other side connected to the ECU. When the ECU needs to change the position of the valve it activates the solenoid by switching the solenoid to ground with a duty cycle signal, creating a magnetic field that pulls the valve to the new position. The duty cycle value affects the position of the valve and therefor the amount of air bypassing the throttle valve.

In this measurement, the used idle air control valve has 2 solenoids. The duty cycle frequency of an idle air control valve solenoid is about 100 Hz, other motor management systems can have different frequencies. The duty cycle signal at idle is usually 40-45% for the opening solenoid and the opposite for the closing solenoid, so 60-55%. In case of a single solenoid idle air control valve only the opening duty cycle applies.

Connecting the lab scope

Correct functioning of the idle air control valve can be checked by measuring the following signal voltages, see figure 1:

| Channel | Probe | Voltage | Range |

|---|---|---|---|

| 1 |  |

Signal voltage opening solenoid | 20 V |

|

Ground at battery | ||

| 2 |  |

Signal voltage closing solenoid | 20 V |

|

Ground at battery | ||

| 3 |  |

Power supply at idle air control valve | 20 V |

|

Ground at battery |

The lab scope is connected to the idle air control valve via a Measure lead TP-C1812B and Back Probe TP-BP85 and is set to recorder mode.

In recorder mode a streaming measurement is performed, continuously displaying the signals live on screen. Because the measured signals vary slowly, the Automotive Test Scope ATS5004D is set to a slow measuring speed.

Measuring

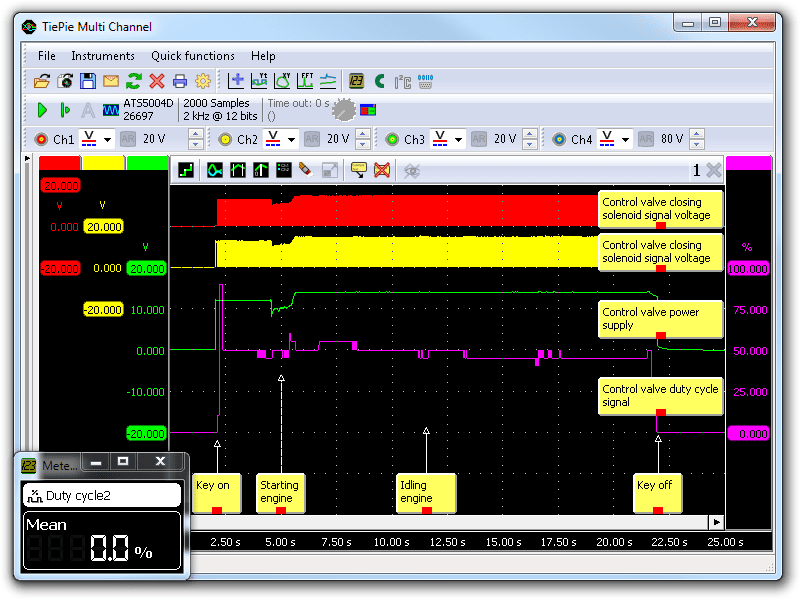

Figure 3 shows a waveform of an idle air control valve of a car under the following conditions: key on, starting engine, idling engine, key off. This signal can be downloaded and used to correctly set up the lab scope or as reference signal.

Download idle air control valve measurement

Channel 1 (red) shows the opening solenoid signal voltage, channel 2 (yellow) the closing solenoid signal voltage and channel 3 (green) shows the power supply voltage. The purple signal shows a calculated duty cycle signal from the opening solenoid, channel 1, and the meter shows the current duty cycle of channel 1. At the beginning of the measurement the key is turned on and the power supply voltage of the idle air control valve reaches 12 V. The duty cycle reaches 100% which means the bypass valve is opened completely, the ECU uses this to reset the position of the idle control valve. Subsequently the ECU sets the duty cycle signal to a setting that matches the current engine state. When the engine is started, the power supply voltage drops because of the engine starting. The ECU increases the duty cycle to allow the intake of air for the cold start. With no acceleration, the ECU adjusts the duty cycle to stabilize the engine speed to the correct idle speed. When the key is switched off, the power supply and the control signals are switched off.

Diagnosis

Signal values may differ on different types of engine control units and idle air control valves. Consult ATIS for information on specific engine control units and idle air control valves.

The following signal deviations can indicate a problem:

-

No signal:

Cause: back probes have no connection (perform a connection test), no power supply to idle air control valve, idle air control valve defective, ECU defective -

Signal voltage too low:

Cause: back probes have a poor connection (perform a connection test), poor power supply to idle air control valve, poor or no ground for the ECU, resistance in wiring to ECU -

Noisy signal:

Cause: wires of power supply or signal damaged, poor connection in connector terminals, defective idle air control valve -

Signal shows an offset in relation to the example signal:

Cause: scope is not set to DC coupling: ,

poor power supply to idle air control valve, poor or no ground for the ECU, resistance in wiring to ECU

,

poor power supply to idle air control valve, poor or no ground for the ECU, resistance in wiring to ECU

RELATED PRODUCTS

RELATED ARTICLES

- Throttle valve control motor DC measurement

- With a lab scope a throttle valve control motor signal voltage is measured with the key on and engine off. The signal from the actuator is shown and can be downloaded. To help determining whether the throttle valve control motor is functioning correctly, different deviations from the example signal are mentioned along with possible causes.

- Throttle valve Position Regulation Step Motor

- With a lab scope throttle valve position stepper motor control signals are measured with a revved engine at operating temperature. The signal from the actuator is shown and can be downloaded. To help determining whether the throttle valve position stepper motor is functioning correctly, different deviations from the example signal are mentioned along with possible problem causes.

This document is subject to changes without notification. All rights reserved.

The information in this application note is carefully checked and is considered to be reliable, however TiePie engineering assumes no responsibility for any inaccuracies.

Safety warning:

- Before measuring, check that sources of dangerously high voltages are switched off or shielded from contact. Voltages considered to be dangerous are voltages over 30 V AC RMS, 42 V AC peak or 60 V DC.

- Keep a clean working environment when doing measurements.

- This measurement and procedures are a examples / measuring suggestions and are no prescribed protocols.

- TiePie engineering can not anticipate the safety actions that need to be taken to protect persons and appliances. Before starting a measurement, check which safety measures need to be applied.