Sensor information

| Type: | Camshaft sensor inductive |

|---|---|

| Power supply: | - |

| Signal type: | Frequency varying |

| Signal level: | ±0.25 V minimum up to ±60 V |

Workings of the inductive camshaft sensor

The inductive camshaft sensor is constructed of a permanent magnet with a coil around it. The magnetic field strength changes when a magnetism sensitive object passes through the magnetic field of the magnet. This changing of the magnetic field induces a voltage in the coil. The polarity of the induced voltage depends on the direction of the moving object, moving away or towards the sensor. This sensor doesn't need a power supply.

In most cases the object used to influence the magnetic field is a cam on the camshaft. Instead, sometimes a metal disk with certain cutouts that pass the sensor is mounted on the camshaft. When the camshaft is rotating and the cam or disk is passing the sensor, the camshaft sensor signal will be an AC voltage of which the frequency and amplitude depend on the rotational speed of the camshaft.

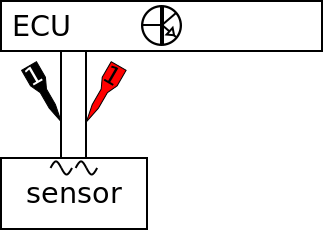

Connecting the lab scope

Correct functioning of the camshaft sensor can be checked by measuring the following signal voltages, see figure 1:

| Channel | Probe | Voltage | Range |

|---|---|---|---|

| 1 |  |

Signal voltage at the positive side of the sensor | 2 V |

|

Signal voltage at the negative side of the sensor |

The lab scope is connected to the camshaft sensor via a Measure lead TP-C1812B and Back Probe TP-BP85. The lab scope is set to normal scope mode with the trigger-timeout at infinite. When a one-shot measurement is started with these settings, the measurement is performed when the engine is cranked.

Measuring

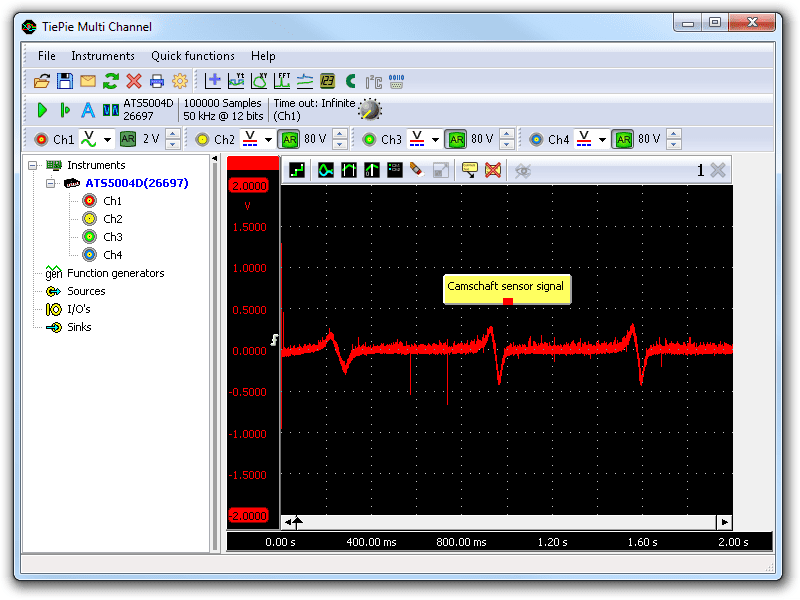

Figure 3 shows a waveform of a camshaft sensor of an engine during cranking. This signal can be downloaded and used to correctly set up the lab scope or as reference signal.

Download camshaft sensor measurement during cranking

Download camshaft sensor measurement on idling engine

Channel 1 (red) shows the signal voltage if the camshaft sensor. The starter motor produces a lot of noise during cranking. This noise has no influence on the performance of the engine management system. The exact amplitude is also not very important. The engine management systems uses the falling edges of the signal voltages to determine the position of the engine.

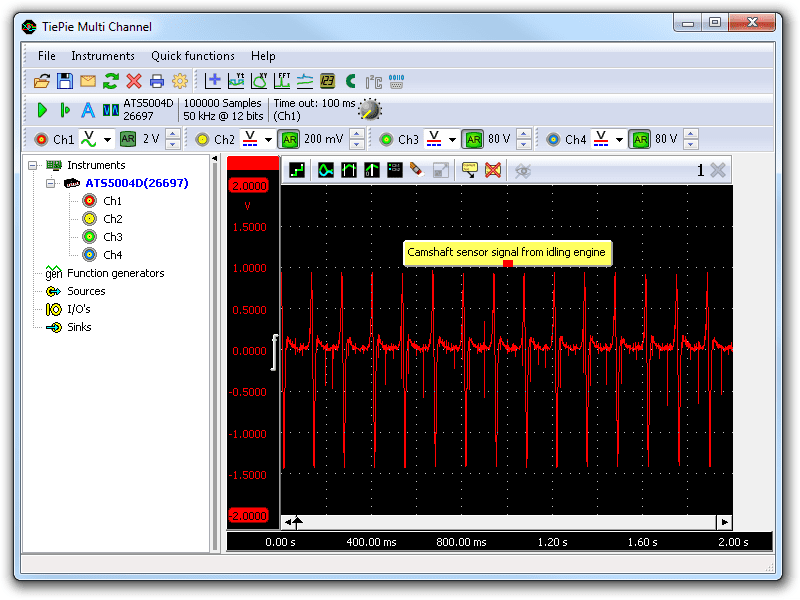

Figure 4 shows the camshaft sensor signal voltage of an idling engine. The amplitude and frequency are clearly higher than during cranking, due to the higher engine speed. The signal also cleaner because the starter motor is not cranking the engine.

Diagnosis

Signal values may differ on different types of engine control units and camshaft sensors. Consult ATIS for information on specific engine control units and camshaft sensors.

The following signal deviations can indicate a problem:

-

No signal:

Cause: back probes have no connection (perform a connection test), sensor loose, sensor defective -

Signal shows more noise than example signal:

Cause: signal wires damaged, poor connection in connector terminals, sensor loose, sensor defective -

Signal shows an offset:

Cause: scope is not set to AC coupling:

-

Signal has faulty pattern:

Cause: cam or disk damaged

RELATED PRODUCTS

RELATED ARTICLES

- Crankshaft Hall

- With a lab scope a Hall effect crankshaft sensor is measured during cranking of an engine. The signal from the sensor is shown and can be downloaded. To help determining whether a Hall effect crankshaft sensor is functioning correctly, different possible deviations from the example signal are mentioned along with probable causes.

- Camshaft sensor inductive

- With a lab scope an inductive camshaft sensor is measured during cranking of an engine, as well as during idling. The signal from the sensor is shown and can be downloaded. To help determining whether an inductive camshaft sensor is functioning correctly, different possible deviations from the example signal are mentioned along with probable causes.

- Xantia refuses to run

- A 1999 Citroën Xantia had a new starter motor fitted, after which it would not run anymore. While cranking it would fire briefly and then die. The car’s battery had been disconnected for the starter motor job. A crankshaft sensor code was logged and thus the crankshaft sensor was replaced, regardless of the good signal. Later the ECM was replaced all with no positive results. The question was if the immobilizer could have reset itself by disconnecting the battery. Proper measuring revealed what the real problem was.

- Troublesome Volvo XC70

- A Volvo XC70 had serious engine related drivability problems. The engine lacked power, would hold back and even stall. Error codes indicated problems in two different areas. Replacing components did not improve things. Proper measuring with an automotive diagnostic oscilloscope revealed two independent problems. Fixing these solved all problems.

- Saab 9-5 with intermittent hiccups

- The engine of a 1999 Saab 9-5 intermittently shows a "hiccup" but then continues to run properly. Over time, the problem became worse and and at some point, the car would not start for 20 minutes. The owner consulted a garage that concluded that the special Direct Ignition cassette needed replacement. Unfortunately that did not solve the problem. Time to start measuring properly, using an automotive diagnostic oscilloscope.

This document is subject to changes without notification. All rights reserved.

The information in this application note is carefully checked and is considered to be reliable, however TiePie engineering assumes no responsibility for any inaccuracies.

Safety warning:

- Before measuring, check that sources of dangerously high voltages are switched off or shielded from contact. Voltages considered to be dangerous are voltages over 30 V AC RMS, 42 V AC peak or 60 V DC.

- Keep a clean working environment when doing measurements.

- This measurement and procedures are a examples / measuring suggestions and are no prescribed protocols.

- TiePie engineering can not anticipate the safety actions that need to be taken to protect persons and appliances. Before starting a measurement, check which safety measures need to be applied.