Sensor information

| Type: | Manifold Absolute Pressure (MAP) |

|---|---|

| Power supply: | From ECU, 5 V and ground |

| Signal type: | Amplitude varying |

| Signal level: | 1.2 V to 4.9 V |

Workings of the MAP sensor

The MAP sensor (Manifold Absolute Pressure) measures absolute air pressure in the inlet manifold. The air pressure in the inlet manifold varies from vacuum to a pressure higher than the normal air pressure in case of a turbo charged engine. The MAP sensor translates the air pressure into a signal voltage that changes with the air pressure. The signal voltage is used by the ECU to determine the amount of air that is going into the combustion chambers.

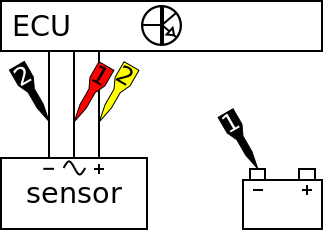

Connecting the lab scope

Correct functioning of the MAP sensor can be checked by measuring the following signal voltages, see figure 1:

| Channel | Probe | Voltage | Range |

|---|---|---|---|

| 1 |  |

Signal voltage output sensor | 8 V |

|

Ground at battery | ||

| 2 |  |

Positive side of sensor power supply | 8 V |

|

Negative side of sensor power supply |

The lab scope is connected via a Measure lead TP-C1812B and Back Probe TP-BP85 to the MAP sensor. The lab scope is set to recorder mode. In recorder mode a streaming measurement is performed, continuously displaying the signals live on screen. Because the measured signals vary slowly, the Automotive Test Scope ATS5004D is set to a slow measuring speed.

Measuring

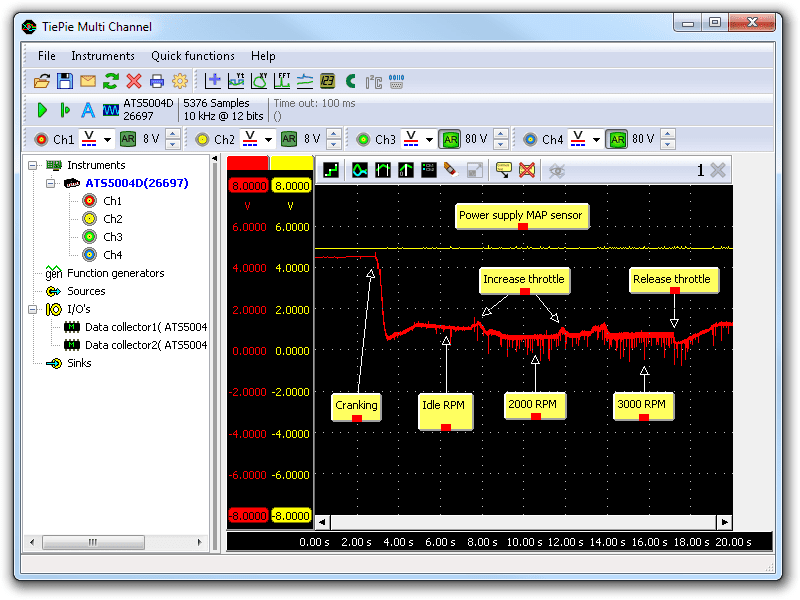

Figure 3 shows a waveform of a MAP sensor of a car with running engine. The signals are measured under the following conditions: key on, cranking, idle, 2000 RPM, 3000 RPM and back to idle. This signal can be downloaded and used to correctly set up the lab scope or as reference signal.

Download MAP sensor measurement

Channel 1 (red) in figure 3 shows the MAP sensor signal. Initially the engine is not yet running and the signal level is around 4.5 V. This signal voltage corresponds to the pressure in the inlet manifold. As the engine is not running yet, this pressure is equal to the outside air pressure. The voltage drops to 0.5 V after the engine fires up and then stabilizes at 1 V. With the throttle in the seated position, only a limited amount of air can pass through, causing a low pressure of 350 mBar in the manifold, corresponding to a sensor signal of 1 V.

Spikes of the ignition are visible in the signals. These spikes have no effect on the operation of the engine management system because the ECU has filtered inputs.

The throttle is opened twice during the measurement to increase the engine speed to 2000 and 3000 RPM. At both moments the pressure increases shortly and quickly drops after that, due to the higher engine speed which demands more air to pass though the engine. At increasing speed, the signal band becomes wider, caused by the larger pressure variations at higher RPM's.

When zooming in on the signal, the individual strokes of the engine become visible from which the engine speed can be determined. Near the end of the measurement, the throttle is released and the signal voltage drops to 0.5 V and stabilizes around 1.1 V at idle speed.

Download MAP sensor measurement zoomed

You can view the signals from this measurement by downloading the measurement and open it in Multi Channel oscilloscope software.

Diagnosis

Signal values may differ on different types of engine control units and MAP sensors. Consult ATIS for information on specific engine control units and MAP sensors.

The following signal deviations can indicate a problem:

-

No signal:

Cause: back probes have no connection (perform a connection test), no power supply, sensor defective -

Signal voltage too high:

Cause: poor or no ground on power supply, vacuum circuit leaking, sensor defective -

Signal shows a lot of noise:

Cause: wiring of signal or power supply damaged, poor connection in connector terminals -

Signal shows an offset:

Cause: poor power supply to MAP sensor, sensor defective

RELATED PRODUCTS

RELATED ARTICLES

- Mass Air Flow (MAF) hot wire sensor

- With a lab scope a Mass Air Flow (MAF) sensor is measured under the following conditions: key on, cranking, idle, 2000 RPM, 3000 RPM and back to idle with an engine at operating temperature. The signal from the sensor is shown and can be downloaded. To help determining whether a MAF sensor is functioning correctly, different possible deviations from the example signal are mentioned along with probable causes.

- Mass Air Flow (MAF) vane sensor

- With a lab scope an air flow sensor is measured under the following conditions: key on, cranking, idle, 2000 RPM, 3000 RPM and back to idle with an engine at operating temperature. The signal from the sensor is shown and can be downloaded. To help determining whether an air flow sensor is functioning correctly, different deviations from the example signal are mentioned along with possible causes.

- Peugeot 205 holding back

- When a Peugeot 205 is performing a strong accelleration, it starts holding back. When it is cruising, nothing is wrong. Several components were replaced, without result. The automotive oscilloscope was used to measure various signals, which led to finding a simple mechanical problem.

This document is subject to changes without notification. All rights reserved.

The information in this application note is carefully checked and is considered to be reliable, however TiePie engineering assumes no responsibility for any inaccuracies.

Safety warning:

- Before measuring, check that sources of dangerously high voltages are switched off or shielded from contact. Voltages considered to be dangerous are voltages over 30 V AC RMS, 42 V AC peak or 60 V DC.

- Keep a clean working environment when doing measurements.

- This measurement and procedures are a examples / measuring suggestions and are no prescribed protocols.

- TiePie engineering can not anticipate the safety actions that need to be taken to protect persons and appliances. Before starting a measurement, check which safety measures need to be applied.